Today the first of 9 Bins at Sheller site was installed. This was the Load & Unload Bin for truck and Rail. The Sheller Feed Building Location is now laid out. The siding Track has been marked out and is waiting for more fill to be done. We now have 2 roads going into Big Rock off of the main Highway "6423". Hagan Bros. Saw Mill has 1 road that enters into the Saw Mill and Dead ends. Sheller Feed has the other that passes the mill and goes on into Big Rock to other locations.

The next items to be built will be the BIG grain Bins that will be located behind the Mill. The big grain bins will hold the grain as the rail cars bring it in as well as the finished feed waiting to be shipped out by either Truck or Rail Car.

Thursday, May 28, 2009

Tuesday, May 5, 2009

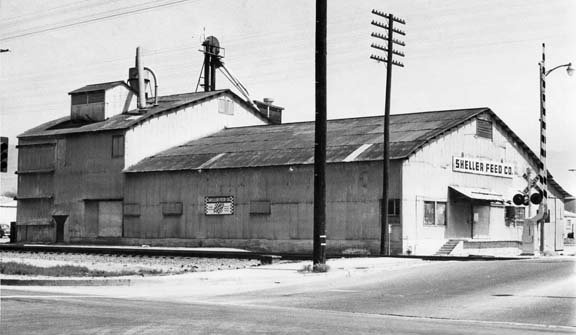

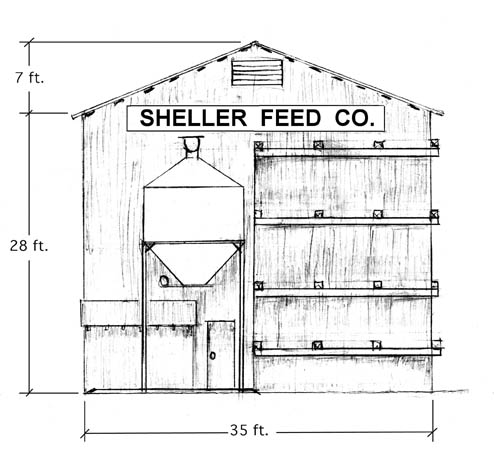

I have been looking for an old mill to model, One industry I found interesting was the Sheller Feed Company located near the city of San Fernando. This industrial structure set along SP's Valley Line heading towards Bakersfield via the Teachappi route. A few diaries and ranches were holdouts at the northwestern end of the Valley as the housing boom approached.

The Sheller Feed Company was built at the time when the San Fernando Valley was mostly farmland. By the 1960s, Sheller was the last feed supplier in the Valley served by railroad. Most business along the SP's, Valley, Coast Line and the Burbank Branch were lumber yards supplying the needs of contractors building new homes and apartment buildings.

Purina was and still is the largest producer of bulk livestock feeds. The feed mill would make up the mix's for livestock, so a number of different commodities delivered by rail, shelled corn, barely oats and soybeans. Without going into details of these how all these commodities were mixed into different feeds, they were sold in bulk or by the sack.

Box cars had a protective paper inside their sliding doors and were spotted next to the taller structure with the receiving chute. The chute can be seen in the picture at the bottom-center of the taller processing structure. This receiving chute would drop down at an angle to meet an open box car door, the inside paper would be cut so the commodity would free fall down the chute for a conveyer to lift and stored in separate bins. After the commodity finished free falling from the box car door, the rest had to be hand shoveled to the ends of the box car. This was hard labor, but at the time labor was cheep.

A feed supplier also received fertilizer and other farm necessities by box car unloading through the to sliding door to be stored inside the warehouse for resale.

I plan on adding Grain Bins to make this a more modern Mill. With the addition of Bins and piping this Mill will be able to load and unload Modern Center Flow Hoppers as well as Receive Box Cars with other Supplies.

The Sheller Feed Company was built at the time when the San Fernando Valley was mostly farmland. By the 1960s, Sheller was the last feed supplier in the Valley served by railroad. Most business along the SP's, Valley, Coast Line and the Burbank Branch were lumber yards supplying the needs of contractors building new homes and apartment buildings.

Purina was and still is the largest producer of bulk livestock feeds. The feed mill would make up the mix's for livestock, so a number of different commodities delivered by rail, shelled corn, barely oats and soybeans. Without going into details of these how all these commodities were mixed into different feeds, they were sold in bulk or by the sack.

Box cars had a protective paper inside their sliding doors and were spotted next to the taller structure with the receiving chute. The chute can be seen in the picture at the bottom-center of the taller processing structure. This receiving chute would drop down at an angle to meet an open box car door, the inside paper would be cut so the commodity would free fall down the chute for a conveyer to lift and stored in separate bins. After the commodity finished free falling from the box car door, the rest had to be hand shoveled to the ends of the box car. This was hard labor, but at the time labor was cheep.

A feed supplier also received fertilizer and other farm necessities by box car unloading through the to sliding door to be stored inside the warehouse for resale.

I plan on adding Grain Bins to make this a more modern Mill. With the addition of Bins and piping this Mill will be able to load and unload Modern Center Flow Hoppers as well as Receive Box Cars with other Supplies.

Subscribe to:

Comments (Atom)